ABSTRACT

PERMETHRIN-IMPREGNATION OF DISRUPTIVE PATTERN COMBAT UNIFORMS (DPCU) is an integral component of personal protective measures adopted by Australian Defence Force (ADF) personnel when operating in an environment with endemic vector-borne diseases. ADF aircrew wear flying suits made from Nomex™ or similar fabric rather than DPCUs. This study compared permethrin-impregnation of Nomex™ and DPCU fabric and the effect of cold-water laundering. It demonstrated that Nomex™ fabric impregnated with permethrin does not achieve the target concentration of 0.120 mg1cm’ promulgated by the ADF The mean permethrin concentration in unwashed Nomex™ was 0.068 mg1cm’, 62.4% of the concentration in unwashed DPCU fabric and 56% of the promulgated target concentration. After laundering, the mean permethrin concentration for Nomex™ fell to 0.0204 mg1cm’, 2l% of that for washed DPCU fabric and 17% of the target concentration. The relation between permethrin concentration and both fabric type and wash-status reached statistical significance (p=0.001). Until the significance of these findings has been established with respect to the risk of vector-borne disease, aircrew should be advised to wear permethrin-impregnated DPCUs for all periods outside flying duty times when deployed to regions for which permethrin-impregnation of clothing has been recommended.

Keywords: Mosquito, permethrin, malaria, flying suits, aircrew, Australian Defence Force

INTRODUCTION

Vector-borne diseases (VBD), such as malaria, dengue, Ross River fever, and Japanese Encephalitis, cause significant morbidity in deployed forces and are endemic in regions where Australian Defence Force (ADF) aircrew deploy. In an attempt to reduce the risk of contracting VBDs, ADF personnel are required to undertake a range of protective measures: wear long trousers and long-sleeved shirts at and after sunset; take approved malaria chemoprophylaxis (e.g. doxycycline); apply DEET (diethyltoluamide)-containing insect repellent to exposed skin surfaces, and impregnate Disruptive-Pattern Combat Uniforms (DPCUs) and bed netting with permethrin.

The combined use of permethrin and DEET is the cornerstone of personal protection of ADF personnel against mosquito-borne disease’. DEET is applied to the skin and acts as an insect repellent; permethrin (a synthetic pyrethroid) is applied to clothing and acts primarily as an insecticide. There is evidence, however, that permethrin also has a repellent action at concentrations below that required for insecticide2J. This integrated approach minimises the transmission of VBDs by preventing mosquito bites on exposed skin or through clothing. The effectiveness of permethrin impregnation of clothing has been documented in a large number of studies. The wearing of permethrin impregnated clothing confers a significant protective effect over people wearing untreated garments, and is said to reduce mosquito bite rates by 90-93%, and provide up to 99.9% protection against mosquito bites when used in conjunction with DEET.

Permethrin-impregnation of DPCUs in the ADF

Australian Defence Force Publication (ADFP) 705 – Pesticides Manual details ADF protocols for the treatment of DPCUs with permethrin. Chapter 2 requires personal equipment (DPCU and mosquito nets) of ADF personnel deploying to a region where there is VBD risk to be treated with permethrin; underwear and DPCU field hats do not require treatment. Clothing to be treated is to be immersed in a solution of 12 m1s of permethrin in 1000mls of water and allowed to soak for up to one hour. When saturated, the DPCUs should be gently hand-wrung to remove excess solution and then air-dried in a well-ventilated, shady area. The ‘target dose’, the residual concentration of permethrin in fabric after the uniform has been treated, drained and air-dried, is 0.120 mg1cm’. The amount of permethrin in DPCU fabric gradually reduces with laundering and ADFP 705 recommends that permethrin-impregnated DPCUs be re-treated after three to four cold-water wash cycles to maintain adequate levels of permethrin.’

Permethrin-impregnation of Nomex™ flying suits.

ADF aircrew are required to wear flame-resistant flying clothing when on flying duty; DPCUs provide inadequate flame-resistance and are not authorised for use by aircrew during flight. Royal Australian Air Force (RAAF) aircrew wear a flying suit made from a blend of Nomex™ and Kevlar™ fibres (DuPont Advanced Fibre Systems, USA), and the newly introduced Australian Army Aviation (AAAvn) flying suit is constructed from a similar fabric made from a blend of meta-aramid, para-aramid, and carbon fibres (aramid-fibre blend, AFB). Until recently, AAAvn flying suits were made from cotton treated with a fire-retardant chemical (Proban’, Albright and Wilson, USA).

AAAvn aircrew wear flying suits as “dress of the day” when deployed, and these are permethrin impregnated in line with ADF protocols. Nomex™ and AFB fabrics, however, have different textile properties to cotton/ polyester blend fabric, so effective impregnation of AFB flying suits cannot be inferred from protocols developed for the treatment of DPCUs. Earlier studies by the US military have shown that permethrin has poor adherence to AFB flying suits. The Armed Forces Pest Management Board (AFPMB) and the US Navy state that although permethrin does not harm the fibres, Nomex™ “flying suits should not be treated with permethrin due to poor adherence and uneven distribution in the fabric”.

It is important to establish the effectiveness of permethrin-impregnation of AFB flying suits. If they cannot be adequately impregnated with permethrin, the practice of wearing AFB flying suits as “dress of the day” means that aircrew are unable to comply with the requirements of ADFP 705.

AIM

The aim of this study was to determine the effectiveness of permethrin-impregnation of Nomex™ fabric treated

in accordance with ADF protocols. The dual hypotheses being tested were that the residual fabric concentration of permethrin in Nomex™ fabric would be lower than DPCU fabric, and that laundering would cause the permethrin concentration in Nomex™ fabric to fall to a greater extent than DPCU fabric.

METHODS

,strong>Treatment phase,/strong>

Two concentrations of permethrin were prepared; a solution prepared in accordance with ADF protocols (12 m1s of permethrin in 1000 m1s of water) – the “standard solution”; and a solution of 24 m1s of permethrin in 1000 m1s of water – the “double strength” solution. Two garments were selected for testing in this study – a RAAF flying suit (93% Nomex™, 5% Kevlar,’, 2% carbon fibre) and a standard-issue ADF DPCU (75% cotton, 25% polyester). The garments were each cut into 10 cm’ sections of fabric and paired for testing. Sixteen fabric sections were soaked in the standard solution and eight fabric sections samples were soaked in the double-strength solution. The paired fabric samples were soaked in the solutions for one hour and then gently hand-wrung to remove excess solution prior to being air-dried.

Washing Phase

After air-drying, the fabric sections were washed in an automatic washing machine (normal wash cycle, small load, cold water) using liquid detergent. The wash cycle time was approximately 38 minutes. In order to simulate a

“small load”, a set of DPCUs was placed in the washing machine and washed with the fabric samples. The samples underwent up to four serial cold wash/air-dry cycles, with one fabric pair being removed after completing cold-water wash cycles one, three, and four. One fabric pair from each treatment method was selected as a baseline and not washed.

Analysis phase

All fabric samples were air-dried for 24 hours and then sent to Defence Science and Technology Organisation (DSTO) for analysis. The samples were analysed by gas chromatography-mass spectrometry (GC-MS), gas chromatography-flame ionization detection (GC-FID), and ultraviolet spectrophotometry (UV).

RESULTS

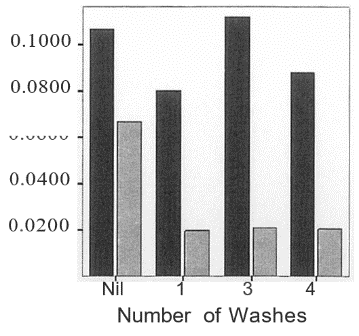

The aggregate results of the permethrin analyses conducted by DSTO were tabulated and processed through a commercial statistical package (SPSS Student Version 11.0). The mean and median permethrin concentrations are presented in Table 1, along with minima, maxima and standard deviations. This data is also displayed graphically in Figure 1. The fabric permethrin concentrations resulting from each analytical method is displayed in Figure 2.

| Fabric Type | Number of Washes | Mean* | Median | Minimum | Maximum | Std. Deviation |

|---|---|---|---|---|---|---|

| DPCU | Nil 1 3 4 |

.1070 .0802 .1122 .0881 |

.1060 .0735 .0999 .0832 |

.0911 .0690 .0966 .0810 |

.1240 .0980 .1400 .1000 |

.0165 .0156 .0242 .0104 |

| Nomexr” | Nil 1 3 4 |

.0668 .0196 .0210 .0205 |

.0637 .0190 .0228 .0195 |

.0637 .0166 .0163 .0150 |

.0730 .0233 .0240 .0270 |

.0054 .0034 .0041 .0061 |

| Nomex™-DS | Nil 1 3 4 |

.1438 .0254 .0150 .0205 |

.1500 .0239 .0146 .0200 |

.1263 .0220 .0110 .0178 |

.1550 .0302 .0194 .0236 |

.0153 .0043 .0042 .0029 |

*Permethrin concentration using mean of all analytical methods.

The mean fabric permethrin concentration of un-washed Nomex™ was 0.068 mg/cm 2, 62.4% of the concentration of un-washed DPCU fabric and 56% of the promulgated target concentration. After laundering, the mean permethrin concentration for Nomex™ fell to 0.0204 mg/cm2, 21% of that for washed DPCU fabric and 17% of the target concentration. The mean permethrin concentration in Nomex™ treated with double-strength permethrin (Nomex™-DS) was 0.1438 mg1cm 2; 35% higher than the unwashed DPCU fabric and 20% greater than the target concentration. This, however, fell to the same mean concentration as Nomex™ treated with standard-strength permethrin solution after a single cold-water laundering.

oPCU

ONomex

| Wash Type | Fabric Type | Mean* | Median | Minimum | Maximum | Std. Deviation |

|---|---|---|---|---|---|---|

| Un-washed | DPCU Nomex™ Nomex™ _DS |

.1070 .0668 .1438 |

.1060 .0637 .1500 |

.0911 .0637 .1263 |

.1240 .0730 .1550 |

.0165 .0054 .0153 |

| Washed | DPCU Nomex™ Nomex™-DS |

.0935 .0204 .0203 |

.0966 .0195 .0200 |

.0690 .0150 .0110 |

.1400 .0270 |

.0210 .0041 |

| .0302 | .0056 |

*Permethrin concentration using mean of all analytical methods.

Data from Table 2 was re-categorised to facilitate statistical analysis. Fabric samples were allocated to one of two categories according to the number of cold-water launderings, washed or unwashed. In addition, the permethrin concentration was stratified according to an arbitrary line selected as being half-way to the 0.120 mg1cm’ target concentration, <0.059 mg1cm’ and >0.060 mg/cm2. These two re-categorisations formed the basis of the following chi-square tables.

FIGURE 2. Permethrin concentration (mg1cm) by analytical method.

| Fabric Type | Permethrin Concentration (mg/cm2) | Total | |

|---|---|---|---|

| >0.060 | <0.059 | ||

| DPCU | 0 | 12 | 12 |

| Nomex™ | 9 | 3 | 12 |

| Nomex™ DS | 9 | 3 | 12 |

| Total | 18 | 18 | 36 |

TABLE 3. Fabric Type vs. Permethrin Concentration

A Pearson’s Chi-Square analysis of the distribution of data in Table 3 was statistically significant (x2 =

18.0, p<0.001), allowing null hypothesis one, that there is no relation between fabric type and permethrin concentration, to be rejected. This x 2 was found to be statistically significant after Wilcoxon Signed Ranks Test for independent non-parametric samples (p<0.02).

| Wash Category | Permethrin Concentration (mg1cm2) | Total | |

|---|---|---|---|

| <0.059 | >0.060 | ||

| Unwashed | 0 | 9 | 9 |

| Washed | 18 | 9 | 27 |

| Total | 18 | 18 | 36 |

TABLE 4. Wash Category vs Permethrin Concentration

A Fisher’s Exact Test chi-square analysis of the distribution of data in Table 4 was statistically significant (x2 = 12.0, p=0.001), allowing null hypothesis two, that there is no difference between fabric washing and permethrin concentration, to be rejected. Mann-Whitney U Test for paired non-parametric samples confirmed the statistical significance of this x2 at p<0.001.

DISCUSSION

The statistical significance of the relation between residual fabric permethrin concentrations and both fabric-type and laundering demonstrated by this study are consistent with other published reports which state that Nomex™ has a poor affinity for permethrin.2.J.9 Further studies may be required to validate these findings for non-Nomex™ AFB fabrics such as those from which the new AAAvn flying suits are made.

This study has demonstrated that Nomex™ flying suits treated in accordance with ADFP 705 cannot be impregnated with permethrin as effectively as DPCUs, and residual fabric permethrin concentrations do not reach the promulgated target concentration of 0.120 mg1cm2. This study also demonstrated that it is possible to obtain a higher concentration of residual permethrin in Nomex™ by treatment with a double strength solution; however, this benefit was lost with the first cold-water laundering and is unlikely to be popular with aircrew.

During the course of this study, several questions were raised. Is wearing permethrin-impregnated clothing with a fabric concentration of less than 0.120 mg1cm2 associated with an increased VBD risk? What is the relative effectiveness of a fabric permethrin concentration of 0.020 mg1cm2 in preventing mosquito bites? Is the mosquito bite-rate through AFB fabric comparable to that of cotton/polyester fabric? Is there an alternate method to treat AFB fabrics that would allow more effective binding of permethrin? These questions exceed the scope of this project but warrant further research and could form the basis of future studies, including surveillance of textile treatment practices that could be used to enhance permethrin binding in AFB fabrics.

This study demonstrates the poor adherence of permethrin to Nomex™. Notwithstanding the un-answered questions mentioned above, the ADF currently requires ADF members to impregnate external clothing with permethrin and promulgates a target fabric concentration of 0.120 mg1cm this target concentration cannot be achieved by aircrew wearing Nomex™ flying suits treated in accordance with current ADF protocols. Aircrew wearing Nomex™ (or similar) flying suits when deployed to regions with endemic VBDs may be at increased risk compared to their DPCU-wearing colleagues. Until the relative efficacy of permethrin-impregnated AFB flying suits has been established and ADF policy has been amended accordingly, aircrew should be advised to wear permethrin-impregnated DPCUs for all periods outside flying duty times when deployed to regions for which permethrin-impregnation of clothing has been recommended.

DISCLAIMER

The views, opinions, and/or findings in this report are those of the author and should not be construed as an official policy of The Royal Australian Air Force or the Australian Defence Force. Citation of trade names in this report does not constitute an official endorsement or approval of the use of such commercial items.